3D laser scanning for the maritime industry

Our team of 3D laser scanning experts are providing multiple solutions for the maritime industry. At first, image there was a technology that could provide a 3D scan of the interior and exterior of a ship, includings all its technological systems. That would be great to manage your fleet.

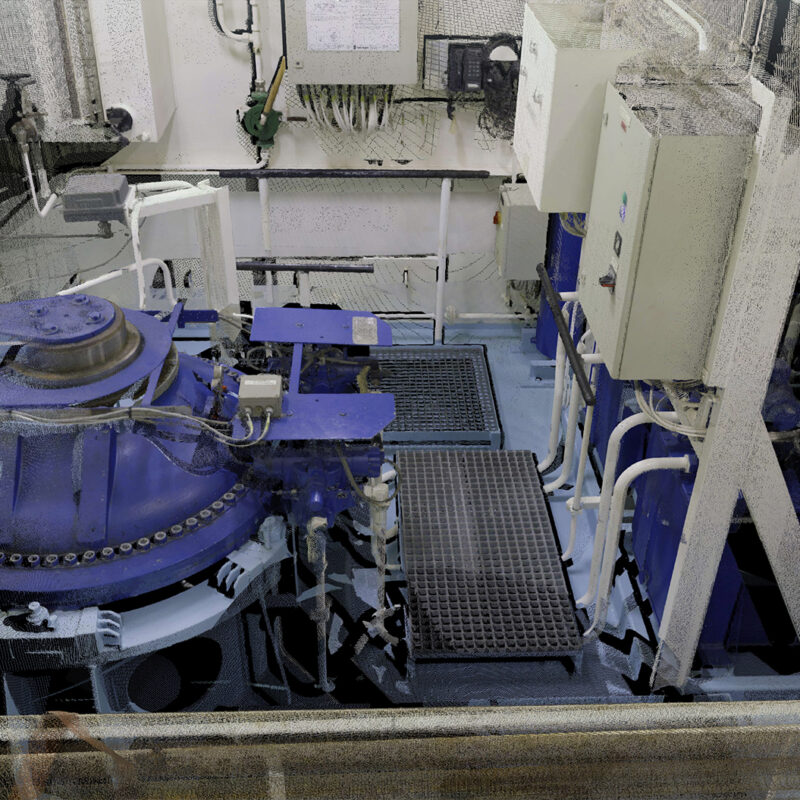

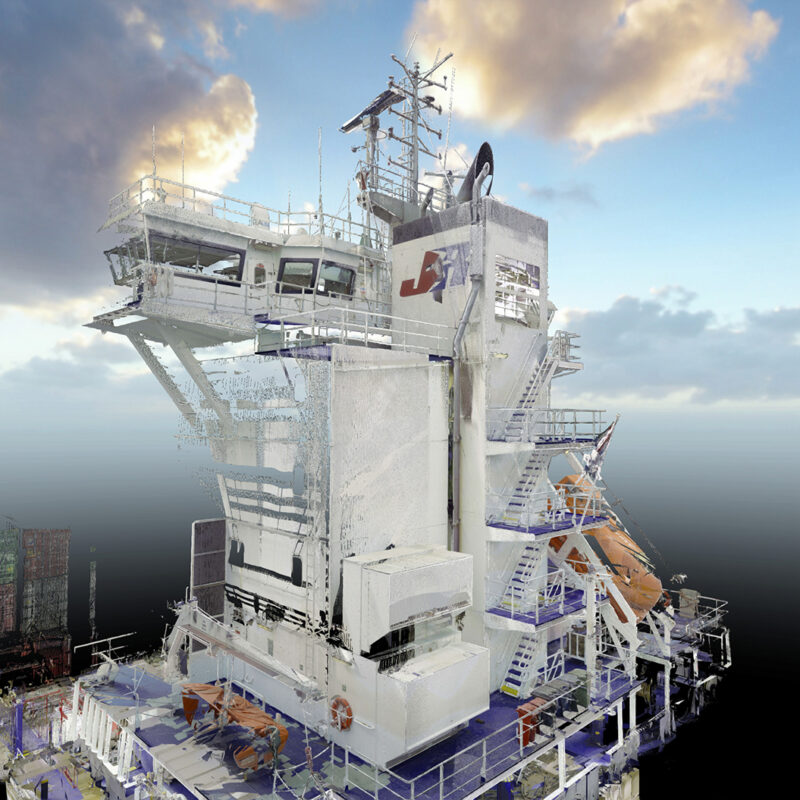

We provide that solution. Our laser scanning team is all around the world to map vessels. Afterwords we start processing the data to provide a suitable solution for every specific issue. For instance when it comes to the installation of the Ballast Water Treatment System, scrubbers or other adaptations at vessels when highly accurate measurements are necessary. Generally, this complete process leads to a high-end 3D point cloud model of the vessel or a specific technological part.

Maintenance and retrofits

Tens of thousands of aging vessels will soon need equipment retrofits. Most of which involves navigating narrow, tight, and limited space areas. Even for owners who have original drawings, those general arrangement depictions may not accurately reflect the current situation on a given vessel. Especially one which has been around for a while. Hence, equipment retrofit is typically extensive, costly, time consuming, and fraught with measurement errors. It does not have to be that way.

Traditional method versus 3D Laser Scanning

Measuring a vessel used to be done by designers and engineers on board, using tape measures or adaptations on the vessel are done without proper preparations (read: prefabrication). Installation will take a while and the ship will be out of operation. On top of that, old school measuring often brings discrepancies between reality and measurements.

Using a 3D scan allows engineering to work in detail with 3D models of machinery spaces with increased accuracy and reduced costs. Engineering is able to prepare the installation or modification completely in advance based on our 3D point cloud model. As a result there will be less failures and it reduces costs. On top of this, laser scanning can be done while the ship is in operation.

The accuracy of the data is enormous. This is the result of the millions of measurement points the laser scanner is taking every second! All of these measurement points are located into the same coordinate system as soon as we are processing the data. In multiple steps of our work process we are verifying the accuracy to be able to deliver a high-end product.

Ballast Water Treatment System

As a consequence of environmental issues and regulation it is necessary to have a ballast water treatment system installed on your cargo ship. Our product is the perfect tool for this water treatment retrofit. Why? The main reason is the tightness and precision that is related to this installation. Most vessels have limited space in the technical room. However this installation should not only fit into this tight room, it also has to connect with the existing pipes at several point. Therefore millimetre level accuracy is necessary.

With a 3D point cloud model, engineering and installation of BWTS is no longer complicated and expensive. The advantages of 3D laser scanning are the reduction in time of installation, the costs and failures. Click here to read more..

Scrubbers

3D laser scanning simplifies the installation and engineering of scrubbers. Scrubbers – exhaust gas treatment plant – are rapidly approaching due to environmental issues and cost benefits related to the changing oil industry. In order to install this system a 3D point cloud model is a clever solution for a quick and accurate engineering and installation.

In comparison with old school measuring, this innovative method guarantees to lower costs and failures and decreases installation time.

Benefits of using 3D laser scanning

- higher level of accuracy compared to old school measuring

- laser scanning can often be done while the ship is in operation

- prefabrication provides a reduction in cost and time

- decrease in failures during engineering and installation

- design and engineering is based on a 3D point cloud model

To conclude, in order to manage your fleet 3D laser scanning is a clever tool that cannot be missed these days. Especially when it comes to ship repair and retrofit operations.

Are you interested if 3D laser scanning is suitable for your maintenance or retrofit project? I am here to answer all of your questions.